Gas Dosing Equipment

Automatic Chlorinator AKN M 3610 C

Full Vacuum Automatic Chlorinator comprising:

- Motor driven V-notch rate valve with 20:1 turndown

- 4-20mA input signal

- 4-20mA valve position output signal

- LED valve position indicator

- Gas flow meter 174mm tube with 4% accuracy

- Differential pressure regulator acc. DIN 19606

- Low and high vacuum switches

- Vacuum gauges

- Inlet vacuum check valve

- Vacuum connections for PE vacuum tubing d8/d10

- Power supply 230VAC 50/60Hz

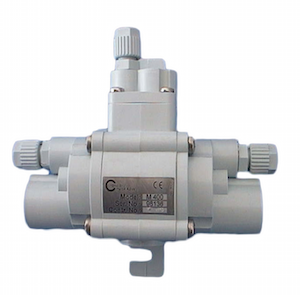

Reinforced ejector M 307 C

Designed to feed gases in high pressure environments.

- High pressure rating up to 20 bar

- Diaphragm-less with ‘O’ ring seal

- Steel counter flanges for high pressure applications

- 1-1/4″ NPT inlet and outlet internal treaded connections

Vacuum Regulators M 20 - M 50

Designed to feed Chlorine, Suphur Dioxide and Ammonia gases.

- Unit works on the safe proven all vacuum principle.

- Dosing range from 200 g/h up to 200 Kg/h.

- Manufactured using high quality chemically resistant materials such as Tantalum, Silver, ECTFE foil, FPM/FKM, PTFE and EPDM.

Manual Chlorinators MR 20 - MR 50

Designed to feed Chlorine, Suphur Dioxide and Ammonia gases.

- Unit works on the safe proven all vacuum principle.

- Dosing range from 200 g/h up to 200 Kg/h.

- System comprises: Vacuum regulators (2), automatic vacuum switchover module, flow meter with manual flow rate adjustment valve, and ejector.

- Option: Motorised valve for automatic dosing (See Model M3600C).

Cabinet Mounted Gas Feeders

- Designed to feed Chlorine, Suphur Dioxide and Ammonia gases.

- Modular design in a free-standing fibreglass floor cabinet.

- Capacity: 200 g/h to 200 Kg/h.

- Can be intergrated into any type of system.

Ejectors

Designed to generate the vacuum required for gas feed systems.

- Capacity: 200 to 200 Kg/h.

- Consists of: Motive water nozzle and throat and gas under vacuum, non- return check valve.

- Options: Basic unit, back pressures < 6 Bar and high pressure ejectors for back pressures > 6 Bar.

Flow Meters

Designed for accurate regulation of the desired gas flow.

- Capacity: 200 g/h to 200 kg/h.

- Consists of: Base plate, flow tube holders, manually adjustable rate valve and glass variable area flow meter with 20:1 turn down and 4% accuarcy.

- Rate valve made of high quality materials.

- Accurate fabrication ensures high precision gas feed.

Automatic Vacuum Switchovers Modules

Automatic switchover from the empty to a full Chlorine source for uninterrupted operation.

- Capacity: 200 g/h to 200 Kg/h.

- All vacuum principle of operation

- Option: Electrical contact that gives a signal indicating that the unit has changed over.

- Manufactured from high quality materials.

Automatic Gas Feeder M 3600 C

Heavy duty performance gas feed unit for accurate, manual or automatic feed of gases into water.

- Capacity: 200 g/h to 200 Kg/h.

- Manual or automatic control valve.

- Vacuum gauge.

- High/Low vacuum switch.

- Manufactured from high quality materials.

- Simple installation, set up and start up.

Evaporator M 3100 C 5

Designed to heat liquid Chlorine or Sulphur Dioxide from 1 tonne drums and convert to high capacity gas.

- Capacity: 40 Kg/h to 200 kg/h.

- Comprises: Regulation, control and safety devices, separate electrical control panel and fibreglass enclosure.

- Low operation and maintenance cost.

- High heating efficiency.

- Manufactured from high quality materials.

Free Chlorine analyser M 1035 C

Designed for measurement and control of Free residual Chlorine in drinking water, waste water treatment and swimming-pool applications.

- Online free Chlorine measurement.

- Proportional and Integral output regulation included.

- Galvanically separated current outputs.

- IP 65 enclosure.

- Two measuring electrodes: Gold/ Copper.

- Microprocessor controlled unit with graphic display.

Temporary Gas Dosing Container

Designed to allow continuation of service while site upgrades and repairs are undertaken.

Equipment housed in a secure, insulated shipping container.

- External enclosures for all connections – water, chlorinated water, power and signals.

- Gas detection system with external alarms.

- Duty / standby cylinders with secure clamps.

- Intelligent heating and ventilation system.

- Proportional gas dosing from 4-20mA input signal.

- Self-contained gas feed system comprising of:

- Motive water pump circuit with injector

- Automatic chlorinator

- Disinfection controller

- Vacuum regulators

- Automatic changeover system

St Michaels Road

Sittingbourne

Kent

ME10 3DZ

sales@chemidose.co.uk

01795 425169