Chemical Dosing Equipment

Dosing Enclosures

Sturdy construction made from 12mm uPVC or PP board designed to suit the customer and application with segregated pump bays and lift-off front panels.

Options include:

- Extraction using chemically resistant centrifugal fans.

- Extraction control panel.

- Enlosure lighting.

- Background heating.

Analyser Arrays

Single or multi-unit analyser boards made from 12mm uPVC board.

- Segregated drain tray to separate buffered and non-buffered waste.

- Option of waste de-chlorination unit.

- In-line pressure reduction and flow control.

- Local sampling facilities.

Dilution Systems

Chemidose Limited offer two versions of dilution system:

- Pumped control using two dosing pumps.

- Simple eductor control.

Chemical Handling

We have many years experience installing chemical handling facilities including:

- Bulk tanks.

- Day tanks.

- Staging.

- Fill panels and associated equipment.

- Conductivity and ultrasonic gauges.

- Pressure transducers.

Controllers

We have many years experience in building a wide range of controllers including:

- Single loop and multi loop chlorination controllers.

- Dilution controllers.

- Extraction controllers.

- Fill panels.

- Alarm panels.

Safety Equipment

To ensure safe installations and ongoing operation, we can supply the following:

- Beacon and alarm stacks.

- Linked forced ventilation.

- Emergency shutdown systems.

- Facility for external telemetry connections.

Temporary Dosing Facility

Designed for simple and quick installation, Chemidose can offer temporary chemical and gas facilities.

- Quick to set up and commission.

- Minimal maintenace.

- Provides stable system while process upgrades and modifications are carried out.

Please also refer to the gas dosing products.

Temporary Gas Dosing Container

Designed to allow continuation of service while site upgrades and repairs are undertaken.

- Equipment housed in a secure, insulated shipping container.

- Gas detection system with external alarms.

- Duty / standby cylinders with secure clamps.

- Intelligent heating and ventilation system.

- Proportional gas dosing from 4-20mA input signal.

- Self-contained gas feed system comprising of:

-Motive water pump circuit with injector

-Automatic chlorinator

-Disinfection controller

-Vacuum regulators

-Automatic changeover system

External enclosures for all connections – water, chlorinated water, power and signals.

Portable Chlorination / DeChlorination Unit

Designed for temporary dosing, utilising de-chlorination / chlorination tablets up to a flow rate of 3,600 l/hr.

Portable unit.

No power required.

Quick and easy connections.

Gas Dosing Equipment

Vacuum Regulators M 20 - M 50

Designed to feed Chlorine, Suphur Dioxide and Ammonia gases.

- Unit works on the safe proven all vacuum principle.

- Dosing range from 200 g/h up to 200 Kg/h.

- Manufactured using high quality chemically resistant materials such as Tantalum, Silver, ECTFE foil, FPM/FKM, PTFE and EPDM.

Manual Chlorinators MR 20 - MR 50

Designed to feed Chlorine, Suphur Dioxide and Ammonia gases.

- Unit works on the safe proven all vacuum principle.

- Dosing range from 200 g/h up to 200 Kg/h.

- System comprises: Vacuum regulators (2), automatic vacuum switchover module, flow meter with manual flow rate adjustment valve, and ejector.

- Option: Motorised valve for automatic dosing (See Model M3600C).

Cabinet Mounted Gas Feeders

- Designed to feed Chlorine, Suphur Dioxide and Ammonia gases.

- Modular design in a free-standing fibreglass floor cabinet.

- Capacity: 200 g/h to 200 Kg/h.

- Can be intergrated into any type of system.

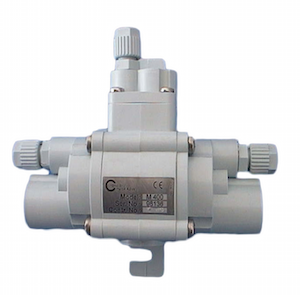

Ejectors

Designed to generate the vacuum required for gas feed systems.

- Capacity: 200 to 200 Kg/h.

- Consists of: Motive water nozzle and throat and gas under vacuum, non- return check valve.

- Options: Basic unit, back pressures < 6 Bar and high pressure ejectors for back pressures > 6 Bar.

Flow Meters

Designed for accurate regulation of the desired gas flow.

- Capacity: 200 g/h to 200 kg/h.

- Consists of: Base plate, flow tube holders, manually adjustable rate valve and glass variable area flow meter with 20:1 turn down and 4% accuarcy.

- Rate valve made of high quality materials.

- Accurate fabrication ensures high precision gas feed.

Automatic Vacuum Switchovers Modules

Automatic switchover from the empty to a full Chlorine source for uninterrupted operation.

- Capacity: 200 g/h to 200 Kg/h.

- All vacuum principle of operation

- Option: Electrical contact that gives a signal indicating that the unit has changed over.

- Manufactured from high quality materials.

Automatic Gas Feeder M 3600 C

Heavy duty performance gas feed unit for accurate, manual or automatic feed of gases into water.

- Capacity: 200 g/h to 200 Kg/h.

- Manual or automatic control valve.

- Vacuum gauge.

- High/Low vacuum switch.

- Manufactured from high quality materials.

- Simple installation, set up and start up.

Evaporator M 3100 C 5

Designed to heat liquid Chlorine or Sulphur Dioxide from 1 tonne drums and convert to high capacity gas.

- Capacity: 40 Kg/h to 200 kg/h.

- Comprises: Regulation, control and safety devices, separate electrical control panel and fibreglass enclosure.

- Low operation and maintenance cost.

- High heating efficiency.

- Manufactured from high quality materials.

Free Chlorine analyser M 1035 C

Designed for measurement and control of Free residual Chlorine in drinking water, waste water treatment and swimming-pool applications.

- Online free Chlorine measurement.

- Proportional and Integral output regulation included.

- Galvanically separated current outputs.

- IP 65 enclosure.

- Two measuring electrodes: Gold/ Copper.

- Microprocessor controlled unit with graphic display.

St Michaels Road

Sittingbourne

Kent

ME10 3DZ

sales@chemidose.co.uk

01795 425169